In these ovens the heat transfer coefficients of the heater gas. Radiation: Heat transfer through radiation takes place in form of electromagnetic waves mainly in the infrared region. Nowadays the reflow ovens apply forced convection heating with nozzle-matrix blower system.

#Reflow ovens series

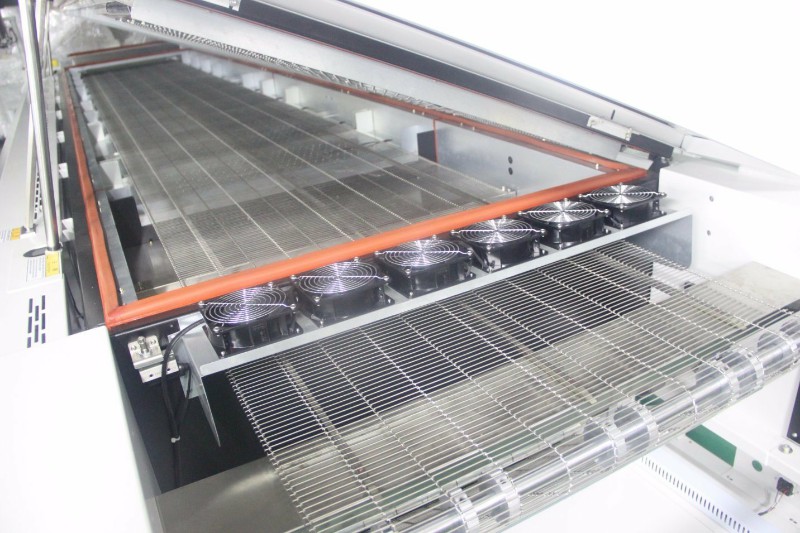

Our Lead-free Reflow Series ovens provide excellent uniform temperature profiling across the board. Heat flows from the warmer to the cooler object until they are both at the same temperature. The ETSMax Lead-Free Reflow Series Ovens deliver high throughput with a choice of eight (8), ten (10), or twelve (12) heating zones and 460mm (optional: 610mm) adjustable wide conveyor for production runs. Innovative developments as process gas cleaning system ABS ensure. Productivity and running costs which directly. It occurs when two objects at different temperatures are in contact with one another other. SMT reflow systems distinguish oneself by long life cycle and high process stability. In a reflow oven, the efficiency of the heat transfer has a primary effect on all aspects of quality.

#Reflow ovens free

Contact BTU with any questions or to learn about the latest advancements in reflow ovens, furnaces, or SMT reflow oven technology.To successfully solder surface mount components to a circuit board, the heat should be transferred to the solder alloy paste until its temperature reaches a molten point (217☌ for SAC305 lead free solder). The Pyramax’s industry-leading “true” ready time allows the oven to recover and reach process stability in record time – enabling the savings without impacting productivity and throughput.īTU’s ovens and furnaces are the industry’s process and productivity leaders and have tens of thousands of installations.

Next, we take on the running cost of the solder reflow oven by automatically lowering the power and process gas consumption during idle time using our EnergyPilot software.

#Reflow ovens generator

We then attack process set-up time through our innovative RecipePro software – the only reflow oven recipe generator to include convection rate in the algorithm, the most important aspect of heat transfer in a convection reflow oven. Our formula is built upon the foundation of the most reliable and repeatable/highest yield system in the industry. Pyramax reflow ovens beat the competition in thermal uniformity, repeatability and exit temperature – even at higher throughput.īTU is focused on minimizing Total Cost of Ownership for the reflow process. For semiconductor packaging, BTU offers nitrogen processing using the Pyramax convection reflow oven with astounding atmosphere purity with O2 levels as low as 2ppm above source in the peak zones. With closed loop convection control the Pyramax reflow oven offers the utmost in process repeatability, board-to-board, oven-to-oven and line-to-line. The Pyramax is known worldwide as the performance leader. Reflow This is the stage where the temperature within the reflow oven is increased above the melting point of the solder paste causing it to form a liquid.

In printed circuit board assembly, surface mount technology SMT reflow is performed by BTU’s Pyramax convection reflow oven. BTU’s convection reflow ovens are used for printed circuit board assembly, semiconductor packaging, and LED assembly among other applications. Typically these applications require high productivity and excellent process control. REFLOW OVEN SOLDER REFLOW OVENS FOR PRINTED CIRCUIT BOARD ASSEMBLY AND SEMICONDUCTOR PACKAGING BTU is the global leader in convection reflow ovens and inline controlled atmosphere furnaces used for the production of electronics andĮlectronic components.

0 kommentar(er)

0 kommentar(er)